Call us: 08042307315

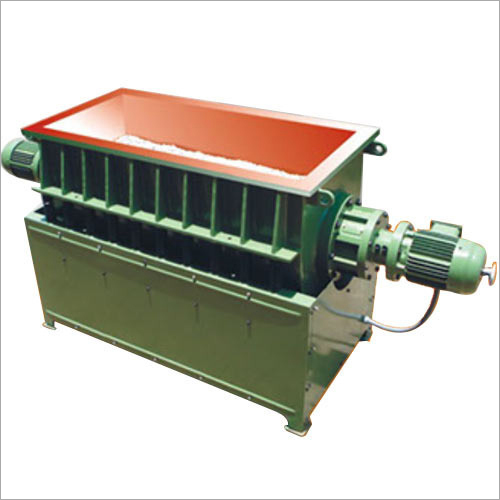

Presenting A Range of Advanced & Resourceful Vibratory Trough Finishing Machine, Semi-Automatic Vibratory Bowl Dryer, Plastic Grinding Media, MS Electric Control Panel, Steel Burnishing Media, etc.

About Us

Since the establishment in 1978, Niraj Optical Machinery has become the leading manufacturer of TASTA mass finishing equipment at Ahmedabad, Gujarat. After vast experience, the company has become one of the biggest names in manufacturing of mass finishing equipment both in India as well as on Global level. We have been holding our strong presence in the marketplace because of superior grade of high performance equipment for the customers that can enhance the overall quality and quantity of work.

Our Mission

Niraj Optical Machinery aims to enhance quality and ensure that TASTA mass finishing equipments become a name to reckon with throughout the world.

Application of Products

Mild Steel, Brass, Aluminum, Zinc, Copper, Ceramic, Plastic & Marble Components like Aluminum Pressure Die Castings, Automobile & Bicycle Components, Aircraft Components, Guns, Bullets, Forgings, Bearings & Bearing Parts, Brass Components, Compressor Parts, Clutch Parts, Electromagnetic Break Parts, Electrical Glands, Hand Tools, Hardware, Imitation Jewelry, Keys & Lock Parts, Machined Components, Pens, Pneumatic Products, Pumps & Valves Spares, Investment Castings, Scissors, Shock Absorbers, Spectacle Frames, Sintered Parts, Switch Gear Parts, Tap Fittings, Watch Cases, Belt Buckles, Pressed Tool Parts, Textile Machines Parts, Zinc Aluminum Based Die Casting, Granites, Marbles, Sand Stone, Slate, Potato Chips, Wheat and many more.

Mass Finishing Process

Mass finishing, also called loose abrasive finishing, is the term most commonly associated with abrasive tumbling operations. Typically a large number of components are placed in the deburring machine and all of them are deburred at the same time. Several different types of machines are used and can generally operate as a batch process or as a continuous flow process.

This process have the additional advantage of being able to finish most exposed surfaces as well as edges of parts. Because they operate on masses of parts, they typically are the lowest cost process for a wide range of components and material. The process is simple to use, and it provide repeatable results. Because the process involves media, compounds and generally innocuous materials, the process considered environment friendly. And all its features make mass finishing machines the work horse of the industries.

Advanced Solution For

|

|

|

|

"Trail Facility Available In Our Lab"

Our Team

We are backed by technically trained and experienced professionals who have deep knowledge in their respective domains. There are several quality traits of our hardworking team members that make ultimate resource for our firm.

For us, client satisfaction comes first. We take well measured actions to ensure their fulfillment and ease at every stage of business. All the processes are operated by us in a fully customer centric way. And, it allows us to provide them a highly satisfactory business experience.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese